At EDGE Garments, we manage the entire shirt manufacturing process in-house — from fabric sourcing and design to production, quality control, and packaging. As an OEM/ODM private label manufacturer, we help brands create shirts based on their custom designs, measurements, and specifications.

With a production capacity of 50,000 units per month, our facilities are equipped to work with established international brands as well as new start-ups and low-MOQ buyers.

Our goal is simple:

Deliver high-quality, custom-manufactured shirts with fast turnaround times and competitive pricing — without compromising quality.

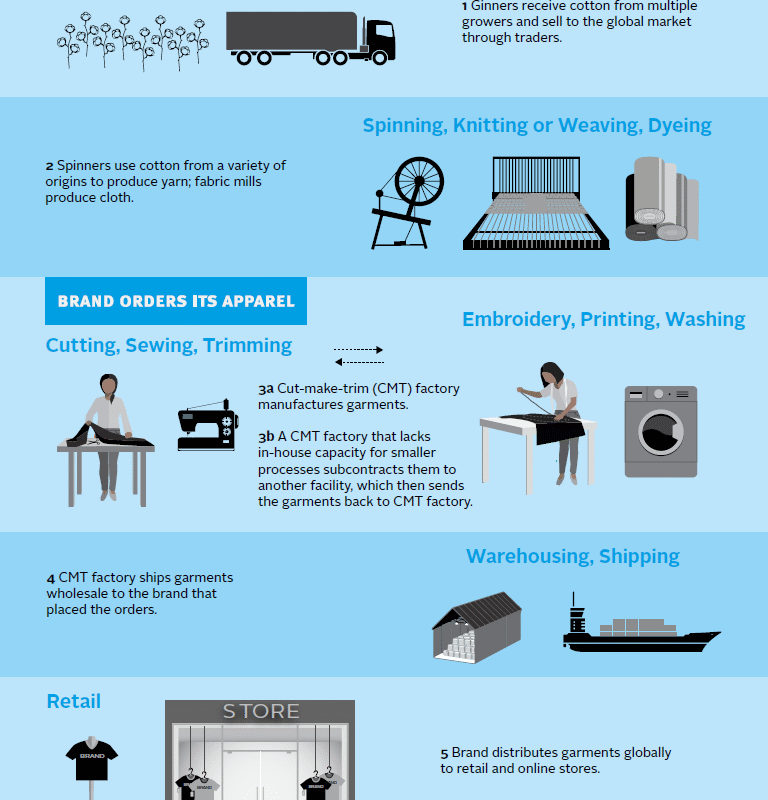

Step 1: Fabric Selection

We only use premium materials to ensure durability, comfort, and long-lasting color.

Available fabric types include:

-

100% Cotton

-

Cotton–Polyester blends

-

Dobby

-

Jacquard

-

Twill

-

Checks, stripes, solid dyed fabrics

-

Printed fabrics

Custom fabric development is available using Pantone color references and detailed specifications.

Step 2: Design, Specification & Sampling

To begin private-label production, clients share:

-

Fabric type & quality

-

Technical sheet / specification sheet

-

Desired measurements or a sample shirt for pattern reference

Once we receive the details, we start sampling, which includes pattern making, cutting, stitching, and finishing.

Step 3: Pattern Making & Cutting

Our team develops accurate patterns and grades them into all required sizes.

Fabric is layered and cut using optimized markers to reduce wastage and ensure precision.

Step 4: Stitching & Construction

The shirt is stitched step by step:

-

Collar & collar band

-

Placket

-

Sleeves

-

Cuffs

-

Yoke

-

Side seams

-

Bottom hemming

-

Buttons & buttonholes

Each stage is closely monitored by supervisors.

Step 5: Quality Control

Quality is checked at multiple points:

-

Raw (greige) fabric inspection

-

Processed fabric inspection

-

Inline stitching inspection

-

Final finishing inspection

Every shirt goes through 100% quality control before packing.

Step 6: Finishing, Packaging & Delivery

Once approved, shirts are:

-

Thread-trimmed

-

Steam-ironed

-

Size-checked

-

Packed in polybags or custom packaging

We provide private label tags, wash care labels, barcodes, and branded packaging upon request.

Production Lead Time

Production time depends on order size and customization.

Typical delivery timeline: 15–30 days.

We confirm delivery dates at the time of order and strictly adhere to committed deadlines.

Minimum Order Quantity (MOQ)

-

150 pieces per style

-

Minimum 50 pieces per color

Low-MOQ orders are also accepted with a small surcharge depending on design and fabric type.

Pricing Policy

We do not offer low-quality products or extremely cheap pricing.

Our focus is on producing premium-quality shirts at fair prices, using high-grade materials and controlled in-house manufacturing.

Contact EDGE INTERNATIONAL

Leading Shirt Manufacturers & Exporters – Ahmedabad, India

📞 +91 99797 55040 / 9426155040